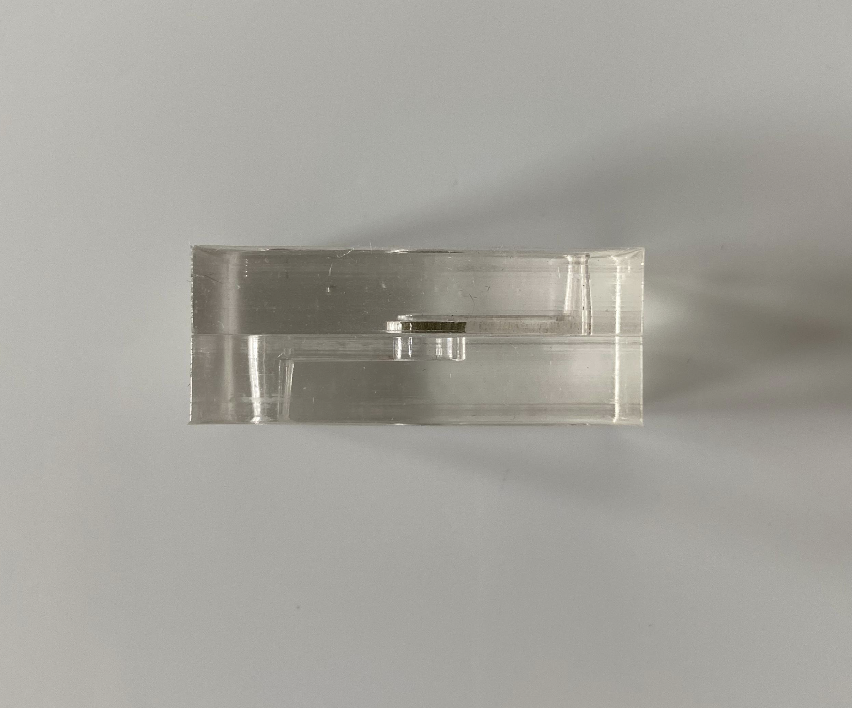

For reliable water in-situ environmental monitoring sensors, a filtration system, made by a double layer microfluidic device and a 3D printed filter, was incorporated into a fluidic sensor system. This design eliminates interfering particles, safeguarding sensitive components and boosting measurement precision and system dependability. It effectively stops particle agglomerates from reaching the detection zone, preventing blockages and preserving measurement accuracy. COMSOL Multiphysics FEM simulations analyzed pressure distribution and additive manufacturing techniques were employed to prototype the system. This filtration system acts as a versatile and crucial extra tool for challenging measurement conditions adaptable to any microfluidic MEMS system.