Power cycling is an effective procedure in devising real-time circumstances that reflect the functioning conditions of electronic components. It yields useful experimental data that offer profound insight into the actual workflow of components and help gain understanding with respect to life, reliability, safety, and behavior in the concerning the case study objectives.

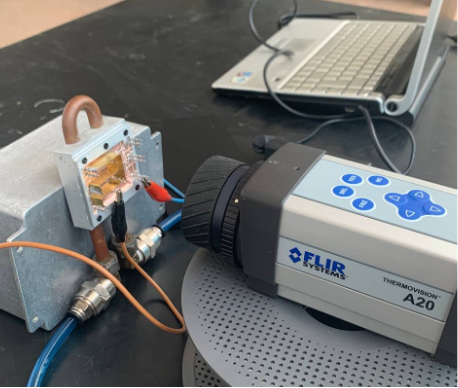

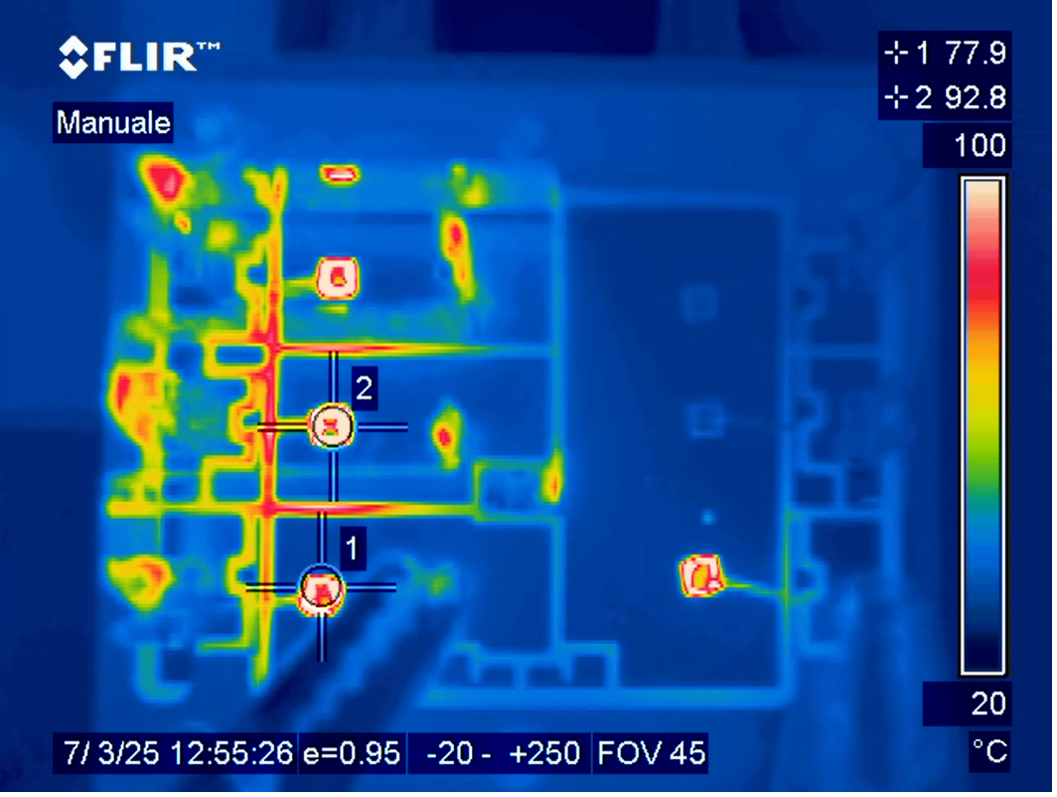

A power cycling procedure was developed to mimic the real-time operation conditions of DBC substrates that were mounted in two different configurations: small single-bonded diodes, and large triple-bonded diodes. The circuit was made in series by including 4 diodes from the overall 6 diodes present on each substrate. The number of cycles were set as 50 with 75% on-time, i.e., 180 s on and 60 s off. A thermal camera, the FLIR Thermovision A20, was utilized to simultaneously log the temperature behavior of the substrates’ surface. Throughout the setup, each DBC substrate that was to undergo the power cycling, was mounted on a cold-plate, over a layer of thermal grease, that was comprised of a water-cooling serpentine embedded in an aluminum platform, providing a relative range of 17 to 19 °C as in cooling. Moreover, they were fixated by means of an aluminum frame, screwed to the cold-plate and holding the DBC substrates in place. Two thermal sensor nodes, i.e., PT1000 Reader, were utilized to make live temperature readings on the ambient and the cold-plate temperature. Electric current was supplied by a power source, namely, CPX400DP that was in turn programmed by the Test Bridge software to realize the cycles automatically, by means of a step wave function.